HOT ROLLING MILLS - LONG PRODUCTS

Blooming Mills, Billet Mills, Heavy Section Mills, Heavy Rolling Stands, PSW Roughing Mills, Heavy Rolling Stands, Complete Bar, Light and Medium Section Mills, Bar Mill Stands, Complete Rod Mills, Monoblocks, Laying Heads, Stelmore Conveyors, Coil Forming Chambers, Rod Mill Compacting and Tying Machines, Coil Conveyors, Reheating Furnaces, Furnace Charging and Discharging Equipment, Hot Descaling Equipment, Cooling Beds, Roller Conveyors, Transfer Tables, Manipulators, Loopers, Special Hot Rolling Mills, Hot Bar Coilers, Controlled Bar Cooling

Stainless Rebar Mill

RLBS-311003

New: 1987, upgrades in the late 1990's, early 2000's; Shutdown: 2003

Manufacturer: Schloemann, Hille Engineering, ABB, Ajax

Configuration: Semi-continuous, Reversing Roughing Stand plus 12 Continuous H-V Finishing Mill

Billet: 4" - 5" (102 - 127 mm)

Products: Rebar: .5" - 1.2" (12.7 - 30 mm); Rounds: .5" - 2.5" (12.7 - 63.5 mm); Square: .625" - 2" (15.9 - 50.8 mm); Hex: .625" - 1.8" (15.9 - 45.7 mm); Flats: .25" x 1.5" - 1" x 4" (6.4 x 38.1 - 25.4 x 102 mm); Angles: 1" x 1" x .125" - 3" x 3" x .375" (25.4 x 25.4 x 9.5 - 76.2 x 76.2 x 9.5 mm)

In-line Bar Quenching

Current capacity is 25 TPH limited by Induction Billet Reheating, can be significantly increased with a gas furnace.

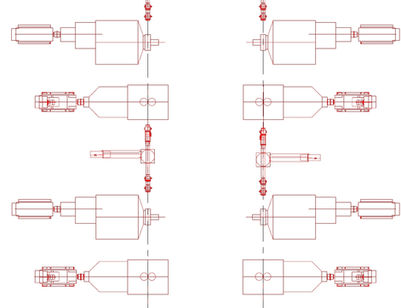

4 Pomini Red Ring Rolling Stands - Fully Reconditioned

RLBS-102682

(2) Horizontal RR445 Rolling Stands:

-

Roll Center: 305 - 430 mm (12" - 16.9")

-

Roll Width: 650 mm (25.6")

-

Components (each): Gearbox with Pinion Stand, Spindles, Spindle Carrier, Base Plate, RR445 Rolling Stand, 2 Spare Stands, Hydraulic Unit, Lubrication

-

Roll Changing Robot

(2) One Convertible and one Horizontal RR436 Rolling Stands:

-

Roll Center: 280 - 345 mm (11" - 13.6")

-

Roll Width: 500 mm (19.7")

-

Components (each): Gearbox with Pinion Stand, Spindles, Spindle Carrier, Base Plate, RR445 Rolling Stand, Hydraulic Unit, Lubrication

-

Convertible Stand with (2) Supporting frames with cylinders for base plate rotation

-

(4) Spare Stands

-

Roll Changing Robot

6" 8-Stand Morgan Rod Block

RLDR-102433

-

Ring Diameter: 147 - 156 mm (5.8" - 6.1")

-

Ring Width: 62 mm (2.4")

-

Max. Finishing Speed: 60 m/s (11,800 FPM)

-

Components: Supporting Frame, Distribution Gearbox, Mill Housings at 45 deg. to the floor.

8"/6" 10-Stand SKET Rod Block

RLDR-102433

-

Ring Diameter:

-

Stands 1-2: 8" (203.2 mm)

-

Stands 3-10: 6" (152.4 mm)

-

-

Max. Finishing Speed: 75 - 80 m/s (14,750 - 15,750 FPM)

-

Currently in as is condition. Would be offered complete with a new Reducer and Distribution Gearbox

10" 4-Stand H-V Sizing / Finishing Block

RLBS-102271

Fully reconditioned

Manufacturer: Danieli

Roll (Ring) Center Distance: 245 - 260 mm (9.65" - 10.24")

Roll (Ring) Neck Diameter: 110 mm (4.33")

Roll (Ring) Width: 80 mm (3.15")

Max. Finishing Speed: 25 m/s (49.2 FPM)

Each Stand driven individually by 250 kW Motor

Two 4-Stand Blocks available

Ajax Magnethermic 25 TPH 5" Billet Heating Line

RHBH-202680

New: 1987. In operation until 2003.

Material: Various stainless steel alloys, Nickel based alloy initial Temperature 70°F (ambient) Final Temperature 2,375°F

Uniformity: 25°F on bar surface end to end at coil exit. Except for leading and trailing bars.

Bar Size: 3" - 5" rounds or 3" to 5" squares.

Bar Length Range: 10 to 30 feet

Bar Weight: 1,200 lb (max)

Bar Surface: As cast. Protective coatings may be used.

Production Maximum: 25 TPH. Some grades that are heated to higher temperatures or have different heating characteristics will reduce production rates,

Hille In-Line Water Quenching System

CLBC-202480

New: 1987. In operation until 2003.

Bar diameter processed: .75" - 2.25"

Max. bar speed: 5.2 m/s through dry tubes and 2.6 m/s through flooded tubes

Number of tube assemblies: 11

Number of trough assemblies: 11

Number of roll assemblies: 12

All tubes, throughs and rollers are submerged in a water tank divided into four sections. The line can be used with water drained for non-cooled products or with water running in tubes only or in fully submerged mode.

Exiting bar is pulled out of the tank by a Pinch Roll located outside the exit side of the tank.